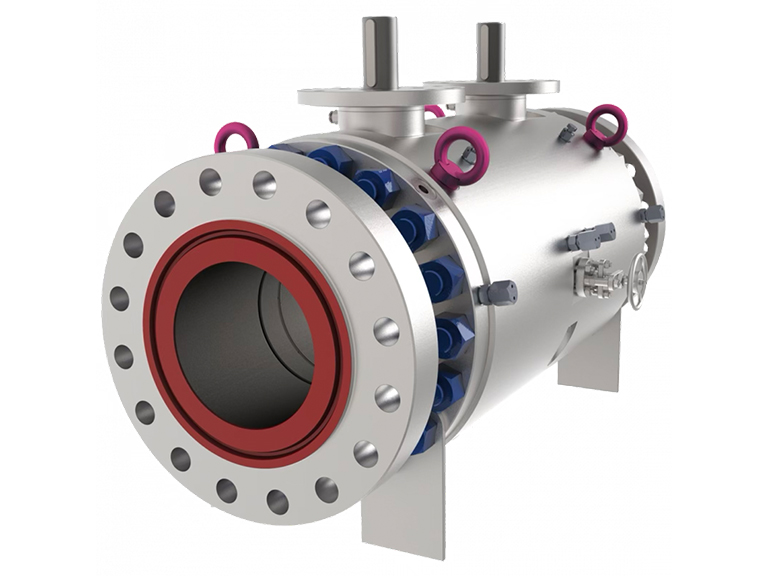

Block And Bleed Valve

OTOM Services supplies high-performance double block & bleed valve (DBB valve) systems designed for safe, compact isolation in critical industrial applications. By replacing traditional multiple-valve setups, these DBB valves provide enhanced safety, minimise potential leak points, and simplify maintenance procedures.

Engineered for durability and reliability, they ensure precise isolation of process lines while reducing operational complexity. Ideal for oil, gas, chemical, and other demanding industries, OTOM’s double block & bleed valves deliver efficient, low-maintenance performance without compromising on safety or operational integrity.

Double Block & Bleed Ball

Double Block & Bleed Ball Valves are equipped with a drain needle, ball or DBB valve mounted between the two balls, this permits to drain the valve and reset the pressure to zero.

The main characteristics of this design is double isolation with two independent balls in one valve body, guaranteeing positive shut off with maximum safety with DIB-1, DIB-2 features.

Design Features

- Size Range: ½” to 3” for Instrumentation / 1” to 36” for Pipeline Valves

- Rating: 150# to 2500#, API 3000 to API 10,000

- Ends: Flanged RF, RTJ, BW, Hub End Connections

Full Bore / Reduced Bore

Soft seated & metal seated

Antistatic and anti blow out stemdesign

Lip seal design

Spring loaded seats

DIB-1, DIB-2

Low emission design

Sealant injection upon request

Cryogenic application upon request - Operation: Lever, Gear, Pneumatic or Electrical Actuator

Design Standards

- Design: ANSI B16.34, API 6D, API 6A, API 608

- Face to face: ANSI B16.10

- Flanges: ANSI B16.5, B16.47

- Top flange: ISO 5211

- Material: NACE MR-0175

- Testing: API 598, API 6D

- Fire safe API 607, API 6FA, ISO 10497

Materials

Carbon Steel, Stainless Steel, Low Temp, Alloy & Duplex Steel

Special testing such as HP Gas Test, IGC, HIC, Fugitive Emission ISO 15848

Part 1 & 2 and also special painting is offered upon request.

Why Choose OTOM Services for DBB Valves

Local Singapore-Based Support

Quick delivery and on-site engineering assistance to keep your operations running smoothly.

ISO-Certified Quality Control

Every valve undergoes rigorous pressure and leak testing to ensure safety and reliability.

Customisable Solutions

DBB valves can be tailored to your specific process requirements and media type.

Comprehensive Valve Range

Access a full selection of valves, including ball valves, gate valves, and knife gate valves, for complete system solutions.

Frequently Asked Questions

DBB valves provide safe and compact isolation in critical process lines, allowing maintenance or testing without shutting down the entire system.

By replacing multiple valves with a single DBB valve, it reduces leak points and ensures a more secure isolation, minimising the risk of process fluid escape.

Yes, OTOM DBB valves can be tailored to suit different media types, pressure ratings, and operational requirements, ensuring optimal performance.

DBB valves are widely used in oil & gas, chemical, petrochemical, and other critical industries where reliable isolation is essential.

Designed for easy maintenance, these valves allow inspection and servicing without removing the entire assembly, reducing downtime and operational complexity.

Contact Us for Enquiries & Valve Solutions

If you’re looking for top-quality valve solutions for your industrial needs, OTOM Services is here to help. Our experienced team in Singapore is ready to assist you in selecting the ideal gate, globe, or other specialised valves for your project. For enquiries or custom orders, reach out to us at +65 66000860 or email [email protected].

In addition to valves, OTOM Services provides an extensive range of products, including offshore handling tools and ROCOL wires , to seamlessly support and enhance your operations.