Check Valve

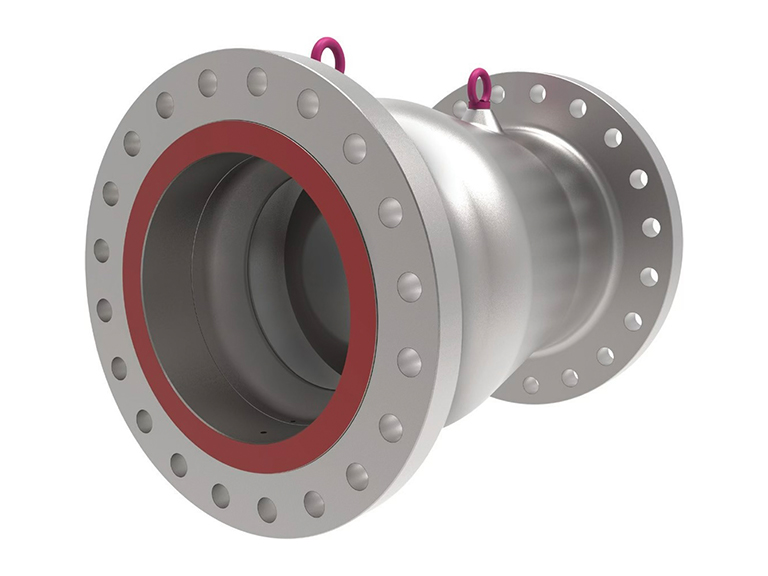

Axial No-slam Check Valves

No-slam check valves are silent in-line and specifically designed to automatically protect critical components from reverse flow as well as pressure transients.

OTOM offers a compact version of the No-slam check valve, providing the same reliability and

quality of the traditional No-slam valves, but with significant space and weight savings. Material selection is fully customizable to meet customers project specifications.

- Metal-seated with hardfacing on disk and seat.

- Powerful spring for ultra-fast closing action.

- Venturi pattern design.

- Minor friction between moving parts to eliminate any chance of jamming.

- Spring assisted and short stroke.

- No chattering effect to minimize pressure fluctuation during normal conditions.

- Low pressure drop.

- High dynamic response and zero reverse flow.

- Nozzle design for valves over NPS 20 for better flow regulation.

- Short pattern design with compact face-to-face option for weight and space savings.

- Valve Design

- Size

- Pressure Rating

- Temperature Range

- Face-to-face

- End Connections

As per API 6D, API 6A, or API 6DSS and customer requirements

Fire safe and fire tested as per API 6FA/607

NPS 2 – 56 (DN 50-1400) NPS 1.13/16- 21.1/4 (DN 46-540)

ASME 150 – ASME 2500

-150 to 662°F (-101 to 350°C)

As per API 6D or API 6A standards Short pattern design as per Velan standard

RF, RTJ as per B16.5 & B16.47

BW, Butt weld as per B16.25 Hub connection

6B, 6BX as per API6A

Swing Check Valve

The swing check valve features a rocker and valve connection designed with a spherical structure. This unique design allows the valve a 360-degree range of motion, providing flexibility and ensuring precise alignment and compensation in its positioning.

- Size: 2”~48”

- Class: 150Lb~2500Lb

- Connection: flange/butt weld

- Temperature: -60°C to +550°C

- Body: Carbon steel(WCB,LCB) / Stainless steel(CF8,CF8M) / Bronze

- Disc: WCB+STL / LCB+STL / CF8 / CF8M

- Design: API 6D / BS 1868

- Face to face: ASME16.10

- Flange end: ASME B16.5 / ASME B16.47

- Butt-welding end: ASME B16.25

- Test: API6D/API598

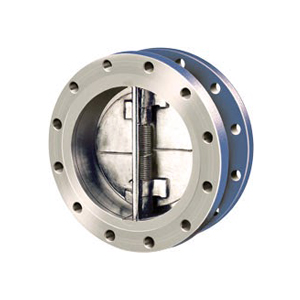

Dual Plate Check Valve

A wafer check valve operates automatically, allowing fluid to flow in one direction. When fluid pressure is applied in the correct direction, it opens the valve flap. Conversely, if the fluid flows back, the pressure pushes the flap onto the valve seat, effectively stopping the flow.

- Size: 2”~40”

- Class: 150Lb~900Lb

- Connection: Double flange / Wafer / Lug

- Temperature: -60°C to +450°C

- Body: Carbon steel(WCB,LCB) / Stainless steel(CF8,CF8M) / Duplex stainless steel(4A,5A,6A)/ Aluminium bronze / Bronze

- Disc: F304 / F316 / C95800

- Spring: SS316 / Inconel 625

- Design: API 594 / BS 1868

- Face to face: ASME16.10

- Flange end: ASME B16.5 / ASME B16.47

- Test: API598

Contact Us for Enquiries & Valve Solutions

If you’re looking for top-quality valve solutions for your industrial needs, OTOM Services is here to help. Our experienced team in Singapore is ready to assist you in selecting the ideal gate, globe, or other specialised valves for your project. For enquiries or custom orders, reach out to us at +65 66000860 or email [email protected].

In addition to valves, OTOM Services provides an extensive range of products, including offshore handling tools and ROCOL wires , to seamlessly support and enhance your operations.